PYROLYTIC CLEANING OVEN

Product Details:

- Product Type Pyrolytic Cleaning Oven

- Weight 250 Kilograms (kg)

- Usage Bitumen Testing Equipment

- Dimension (L*W*H) 31 x 37 x 60

- Equipment Materials Power Coated / Painted / Chrome Plated

- Power 240 V, 50 Hz., Single Phase

- Application The Pyrolytic Oven is used for performing safe, solvent-free cleaning of asphalt and other organic residues from glass and labware.

- Click to View more

PYROLYTIC CLEANING OVEN Price And Quantity

- 300000 INR/Piece

- 1 Piece

- 350000.00 - 500000.00 INR/Piece

PYROLYTIC CLEANING OVEN Product Specifications

- Power Coated / Painted / Chrome Plated

- 31 x 37 x 60

- 240 V, 50 Hz., Single Phase

- The Pyrolytic Oven is used for performing safe, solvent-free cleaning of asphalt and other organic residues from glass and labware.

- Pyrolytic Cleaning Oven

- Bitumen Testing Equipment

- 250 Kilograms (kg)

- 1 Year

PYROLYTIC CLEANING OVEN Trade Information

- 100 Piece Per Month

- 4 Week

- Contact us for information regarding our sample policy

- Wooden Box / Corrugated Box

- ISO 9001 : 2015

Product Description

The Pyrolytic Oven is used for performing safe, solvent-free cleaning of asphalt and other organic residues from glass and labware. Even trace residues of organic contaminants from asphalt, injection molding, and organic chemistry applications are removed, leaving lab equipment ultra-clean for critical testing This cost-effective, fully automatic method saves time and creates a safer, more efficient lab environment. Costs and risks of hazardous waste handling and disposal, glass breakage, and labor are reduced or eliminated. Lab technicians no longer need to rely on scraping, wire brushing, or hand heating to clean bitumen or other organic residues from the glassware. Operators can simply place everything in their pyrolytic oven, press start, and allow the machine to do the work. This not only reduces mess, but saves time and creates a safer, more efficient lab environment. Maximum oven temperature is 482C and cleaning temperatures range from 426C to 482C to burn off organic contaminants, leaving behind only carbonized residue, which can be easily removed.

Further details available on our website.

Price and specifications mentioned here are subject to change as per the application, customer requirements and prevailing market conditions. Please refer to us for the final rates and offer.

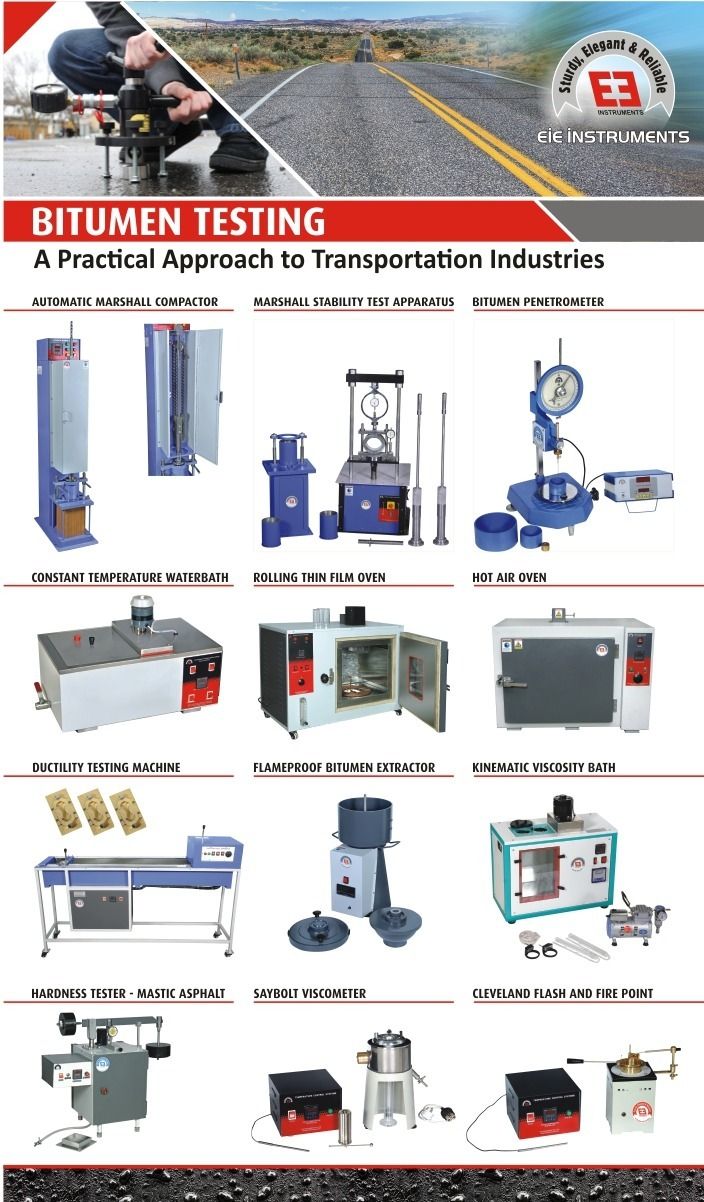

Other Products in 'Bitumen Testing Equipments' category

|

EIE INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |